The main theme of this paper is the usage of the advanced time-dependent elasto-plastic material model for diaphragm walls modeling. First, a theory of time-dependent behaviour is briefly introduced. Next, the Shotcrete material model is described and calibration of materiál model in long term conditions based on laboratory testing is done. Finally, a real boundary value problem of deep excavation supported by diaphragm walls with the strut is solved. Reached values of intemal forces and deformations reached using different modelling methods are compared and discussed.

Archiv článků od 6.3.2023 do 10.6.2024

The paper focuses on the issue of permitting the construction of apartment buildings in the period of the First Republic, with a focus on the then building regulations. The paper uses the example of the construction of a specific apartment building in Brno to present the then system of building permits, selected technical requirements for the construction of apartment buildings, including the cost of permits and the possibility of obtaining a state contribution for construction.

In the presented paper, the results of the use of modified gypsum-based recyclate obtained from construction and demolition waste are analyzed. The selected recyclate comes from a real construction site of Moravostav Brno, a.s. and was subjected to modifications using a newly developed gypsum plasterboard recycling line. During the research, the influence of the recyclate treatment, especially in terms of grinding fineness, on the key properties of the dry gypsum mixture was monitored. Substitution of gypsum (or gypsum binder) in the mix was carried out in proportions of 10, 25 and 50 wt%. The resulting properties, such as bulk density, flexural tensile strength, compressive strength, volumetric changes and shrinkage, were monitored after 7 days of sample production.

In a follow-up step, gypsum blocks using treated gypsum recyclate and the designed dry gypsum slurry were semi-produced at Moravostav Brno, a.s. in January 2024. A segment of the wall was constructed from the blocks.

The results obtained clearly show that with appropriate treatment, it is possible to effectively replace part of the gypsum binder in the dry gypsum mixture using modified gypsum recyclate. These findings provide important information for the advanced use of gypsum plasterboard recycling in the construction industry, while highlighting the potential for more sustainable and environmentally friendly practices in building materials.

This article deals with the possible combination of high temperature fly ash with fluidized fly ash. The aim of this experiment is to verify the influence of the combination of these two secondary energy products not only on the parameters of cement mortar in its fresh state, but especially on its mechanical parameters in its hardened state.

By digitizing and automating processes throughout the building life cycle, the goal is to optimize the use of information so that it can be easily used either to reduce waste from buildings (waste prevention) or to have sufficient information about the materials and products used in the building at the end of its life cycle or as part of various renovations or retrofits. At the same time, improving the planning and management of the waste generated is a key effort. The paper presents the results of the European RECONMATIC project in this area, which progressively links information efficiency approaches with BIM processes. As such, the project has a broader focus and represents a paradigm shift in the management of C&D materials, from the traditionally conservative approach to C&D waste, to a similarly conservative approach of the construction industry, to construction production that seeks to achieve high waste recovery rates, and to the adoption of a responsive approach to waste recovery. The technologies to be used in this project (creating and working with a digital twin of the building, blockchain-based applications, precision prefabrication, efficient sorting through automation and robotics, etc.) are part of the themes that the project focuses on.

This paper presents research focused on studying the behaviour and properties of wood-cement composites under changes in relative humidity. The behaviour and the resulting changes in properties with variations in air (relative) humidity are significantly influenced by the chips contained. The chips are mineralised or stabilised during the manufacturing process. The by-product (particle mixture) from the production of cement-bonded particleboards, which was used to modify the composition of the composites, already contained mineralised spruce chips (i.e. stabilised properties and structure). The goal of the research was to study the sorption mechanisms in terms of dimensional and volumetric changes, including the assessment of the composite materials' performance properties (density, strength characteristics and modulus of elasticity). Thus, the influence of spruce chips stabilization in terms of different matrix compositions of the composites was also partially, indirectly analysed. Three variants of composites were tested - 2 types of reference (based on Portland and blended cement); 1 type with modification of the binder and filler with particle mixture produced during the production of cement particleboards (4% cement substitution, 4% substitution of primary chips). For the determination of each point of the sorption curves, the test bodies were always exposed to a given moisture content for a period of time to allow their mass to settle. The sorption isotherms indicate the different behaviour of the plates during the increase and decrease of the ambient air humidity. Differences were also observed in the case of hysteresis. The modification of the composition of the mixture for the production of cement-bonded particleboards has an effect, among other things, on the stabilisation of the spruce chips. The changes in physical and mechanical properties are practically negligible in terms of the practical use of the boards with modified composition.

This article deals with the possibility of assessing the k-value of power plant fly ash using durability. For cement mortars with replacement of 10, 20 and 30 % of Portland blended cement with fly ash, compressive strengths, efficiency indices, depth of talc water seepage and depth of carbonation were determined for ages of 7, 28, 60 and 90 days. For individual cement substitutes, k-values were determined for a given age using the relationship between water coefficient and compressive strength. According to the results of the hardness tests, the determined k-values were assessed and the k-values that are safe for the use of power plant fly ash in the aggressive environment XC and XD were determined.

This article follows up on Part 1, which dealt with the theoretical knowledge of partial fire protection of steel structures. It focuses on experimental work and numerical models, supplemented by parametric studies. Experiments were conducted on four steel samples, each subjected to a standard fire temperature curve for 60 minutes. The samples were tested with various thicknesses of coatback to determine its impact on the thermal behavior of steel. Numerical models were developed based on the experimental data and used for parametric studies, which examined the impact of various variables, such as the length and thickness of fire protection, on the temperature at the junction of the beam and column. The results show that the thickness and length of fire protection significantly influence the thermal stability of steel structures and can be used to design effective fire protection measures.

This article focuses on the partial fire protection of steel structures and provides a theoretical review of current methods and materials used in this area. Various types of passive fire protection systems are introduced, including intumescent coatings and their influence on heat transfer between protected and unprotected parts of the structure. The article deals with analytical and mathematical methods for determining the thermal properties and fire resistance of the materials used, with an emphasis on those that undergo thermal degradation. This article offers a comprehensive view of the theoretical foundations of partial fire protection of steel structures and proposes directions for further research in this area, providing a basis for Part 2: Experiments, Numerical Models, and Comparisons.

The article is focused on the issue of traditional timber joist floor structures and floor compositions from the period up to the first half of the 20th century. In building practice, we very often encounter these structures in residential buildings that are the subject of structural changes. During these interventions, the basic ideas of the original technical solution are not always respected and some physical parameters of building are degraded. The article describes the principles that were devoted to these types of structures in historical legislative and standard regulations and further in professional literature. The original historical solutions are presented on a practical example. In relation to building interventions in historic timber joist floor structures, current legislative and standard regulations are described, as well as examples of modern solutions and their limitations.

The article is focused on the issue of traditional timber joist floor structures and floor compositions from the period up to the first half of the 20th century. In building practice, we very often encounter these structures in residential buildings that are the subject of structural changes. During these interventions, the basic ideas of the original technical solution are not always respected and some physical parameters of building are degraded. The article describes the principles that were devoted to these types of structures in historical legislative and standard regulations and further in professional literature. The original historical solutions are presented on a practical example. In relation to building interventions in historic timber joist floor structures, current legislative and standard regulations are described, as well as examples of modern solutions and their limitations.

The prepared experimental program focused on the shear resistance of presstressed beams with bonded tendons needed to develop a parametric study, focused on the shear resistance of the designed beams. In the contribution, a parametric study of beam with I - cross section type DPS VP I/10 with total length of 7,0 m and a height of 0.6 m with different levels of prestress and different levels of shear reinforcement is processed. The standardized reinforcement of the cross-section used in practice is supplemented by longitudinal bars. Different design approaches were used to determine the shear resistance of the beam.

This paper deals with the effect of recycled aggregate in concrete beams that are subjected to flexural and shear stresses. The beams are reinforced with two types of longitudinal bearing reinforcement. The reliability factor is slightly reduced. For concrete with recycled aggregate, it is 3 % for EC2 and 5 % for prEC2. For concrete with recycled aggregate, brick aggregate it is 13 % for EC2 and 14 % for prEC2.

The reduced modulus of elasticity does not affect the results. The coefficient of variation for reinforced beams GFRP reinforcement is 6.98 % for beams with 10 mm reinforcement and 9.40 % for beams with 16 mm reinforcement. The coefficient of variation for beams reinforced with 10 mm diameter steel reinforcement is 16,79 %, and for beams reinforced with 16 mm diameter steel reinforcement is 9,87 %

Modern trends in civil engineering are focused at reducing the comprehensive carbon footprint. One way to reduce a building structure's carbon footprint is to replace conventional building materials with suitable alternatives from recycled materials. These products also include recycled steel fibers from waste tires, which have a great potential for use in the form of dispersed reinforcement in concrete. Waste material from industrial production thus creates the possibility of its transformation into a recovered raw material within the so-called circular economy. This paper is focused on evaluation of the fibers in terms of geometric and mechanical properties, as well as experimental research on the properties of fresh and hardened concrete with different doses of recycled steel fibers.

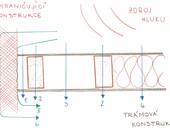

This paper deals with the study of the effect of the use of styrene in a polyester resin as a polymer binder in a trenchless rehabilitation composite. The different formulations also contain secondary raw materials as waste foam glass, basalt frit, waste glass from solar panels and fly ash. In the development of the formulations, which are subsequently used to saturate the polymer sleeves, the influence on the mechanical properties of the whole composite is mainly investigated. The mechanical parameters investigated include mainly the flexural modulus, the stress at first failure, the flexural deformation, adhesion of the lining to the pipe. The work found that the decrease in mechanical properties for the non-styrene variant is not so significant as to prevent its effective use in the composite.

In the past, natural stone was among the most used building materials in the Renaissance and Gothic periods. On the territory of the Slovak Republic, sandstone was used for its suitable properties, good compressive strength, appearance, and good machinability. Sandstones still form the supporting elements of sacral and public historical buildings. These building structures are exposed to the weather because the surface finish consists of capillary-active materials or none. From the point of view of monument protection, it is not possible to propose hydrophobic modifications and therefore water coming from driving rain can be absorbed into these structures of historical buildings. This article describes the absorption and redistribution of water in structures using one-dimensional computational simulations of liquid water transfer in selected sandstones from eastern Slovakia using a simulation tool. The results are compared with German sandstones.

In the Czech Republic, a preparation of high-speed lines construction according to principles adopted from France is currently in process. Its substructure is among others to be made of an asphalt concrete layer. Nevertheless, the requirements on asphalt mixture properties cannot simply be taken from the French standards, as a different procedure for the compaction of test specimens, which are used for mechanical and functional tests, is used in the Czech Republic. This paper presents the results of an experimental study that compares the impact of test specimen compaction methods used in the Czech Republic and in France on selected properties of asphalt concrete. As a part of the study evaluation, a mutual correlation between individual compaction methods is identified and discussed.

This article deals with the issue of the use of construction and demolition waste in concrete. Primarily with regard to the testing of recycled fine aggregates using today's current standards for concrete aggregate. Three main representatives of recycled aggregates are tested, namely concrete aggregate, brick aggregate and mixed recycled aggregate. Subsequently, recycled aggregate is used for concrete production where it forms a substitute for fine aggregate at 33, 66 and 100 wt%. A series of tests were carried out on 150 × 150 × 150 mm concrete test speciement to determine basic properties such as bulk density, water absorption and compressive strength.

One of the possible solutions for using up used tires is the construction industry. By incorporating waste rubber and reinforcement from tires into concrete, it is possible to partially replace natural aggregate and manufactured reinforcement. This solution should help reduce the negative impact of waste tire disposal on the environment.

Alkali-silica reaction of aggregate with components of cement (AE - Alkaline Expansion) are among the factors causing degradation of concrete. Within a few years or decades of concrete aging, at the surface of aggregates containing reactive form of silica, a cover layer occurs. This layer is capable of expansion due to water absorption. The process is called alcali-silica reaction (ASR).

zpět na aktuální články