Failures occurring on the facades of assembly houses often arise due to volume changes sunlit walls and incorrectly made contact details between panels. Sometimes it is not enough to eliminate them or repeated repair of damaged joints. Therefore is no choice of other solution than to overlap these joints with thermal insulation system. One such case is the subject of this paper.

Archiv článků od 10.2.2014 do 14.4.2014

This paper deals with the experiment which was used to analyse the influence of duration of cement hydration on the concrete properties. Compressive strength of concrete and dynamic and static values of the concrete modulus of elasticity were determined. The only variable factor was the duration of cement hydration. The outcome has form of graphic and tabular outputs showing the observed values.

The paper deals with the main rules for inclined roofs design from the thermal protection of buildings perspective in the first row. The text follows up the composition of these structures with the respect to the position of thermo insulation layer and in depth discuss the important rules for quality design both individual roof structures layers and whole roof compositions.

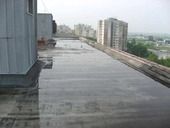

By flat roof reconstruction of panel apartment houses we meet quirements for hygiene, health, inerior environment, thermal protection and energy consuption. This paper deal with these problems. There are also mentioned actual conditions of flat roofs and principles of their reconstruction. Moreover paper contains example of wrong reconstruction of panel house.

An overview of the development and standard types of the prefabricated wooden houses, their basic structural materials, basic mechanical timber joints, design practice for loads effects and requirements for structural elements is presented in the five-part series. In the third part basic mechanical timber joints are dealt with.

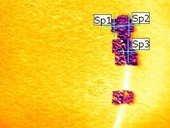

One of the most discussed questions during the last few decades is the functionality of inverted roofs, with the thermal insulation of low water absorbing extruded polystyrene.

The main question is the one of heat loss caused by the cold rain water penetrating through the joints between the boards of thermal insulation itself and going towards the water outlet system beneath this insulation, respectively directly on the waterproofing. The snow melting period seems as the most serious from this point of view.

Two test sample frames were prepared for the purpose of investigation of this phenomena. One of them simulating the rain water outlet above the roof edge flashing and the second one for the simulation of outlet through the inner roof gully. The ratio of undergoing water in the various roof slopes in condition of artificial rain was measured. The ratio of undergoing water was actually high and that it decreased with the increasing slope, depending also on the scheme of water outlet. In case of installation of standard breathing membrane with the low equivalent diffusive thickness placed in the position of separation layer between the XPS insulation boards and the gravel ballast layer ratio of undergoing water became to be nearly inverted. This breather membrane took the function of certain rain water barrier in the structure.

An overview of the development and standard types of the prefabricated wooden houses, their basic structural materials, basic mechanical timber joints, design practice for loads effects and requirements for structural elements is presented in the five-part series. In the second part basic structural materials are dealt with.

In October 2013 in Orange County Great Park in city of Irvine, California, took place the sixth edition of the prestigious international competition of universities U.S. Solar Decathlon 2013. This round took part also Team Czech Republic from the Czech Technical University in Prague, which finished at overall third place. The article describes in detail building services used in the AIR House.

The article draws attention to situations, which are created when cracks in concrete and reinforced concrete structures are evaluated. Despite cracks being in general allowable in reinforced concrete structures as per ČSN EN 1992-1-1, only the width of cracks must be limited with respect to functionality of the structure. These limits are well defined with respect to water impermeability of reinforced concrete structures or their durability, but we are missing criteria, which would allow for evaluation of influence of the cracks on visual appearance of the structures. Therefore very frequently situation arises, when cracks are not warranty claimed as a potential static defect or a flaw, or as an aspect influencing lifespan of the structure, but solely as an aesthetic defect.

In October 2013 in Orange County Great Park in city of Irvine, California, took place the sixth edition of the prestigious international competition of universities U.S. Solar Decathlon 2013. This round took part also Team Czech Republic from the Czech Technical University in Prague, which finished at overall third place. The article describes in detail rules of competition and technical solutions used in the AIR House.

The paper describes the basic division of surface protection systems for concrete, which define standard EN 1504-2. Evaluates various parameters prescribed in relation to the requirements of the usual structures and gives appropriate use of various systems. The following are examples of inspections carried out and assessed defects.

This Article focuses on the significant changes to the Land Register introduced by the New Civil Code and an act no. 256/2013 Coll. The most important change is the strict application of the principle of material publicity – in contrast to the previous legislative regulation the record in the Register is always the decisive factor for determining the existing rights. The recording of real rights proceedings improves the protection of real estate owners from fraud by mandatory informing them about the proposed changes. The real right will not be recorded until 20 days after informing the owner.

The priority principle is strengthened by marking not only days but also hours and minutes of submitting the proposal of real rights record. An existing real right which was not a subject of mandatory record before has to be recorded by January 1, 2018. Neglecting this duty might result in losing the right in favor of an incompatible right recorded later.

The real rights are now recorded uniformly regardless if they originate through a contract, court decision, auction etc. Rights such as lease can also newly be recorded in the Register. The changes also reflect the newly introduced principle in the Civil Code making the ownership of the buildings inseparable from the ownership of the land beneath. This principle does not extend to the buildings and land which had different owners before January 1, 2014, temporary buildings and the buildings built entitled from the right to build.

An overview of the development and standard types of the prefabricated wooden houses, their basic structural materials, basic mechanical timber joints, design practice for loads effects and requirements for structural elements is presented in the five-part series. The first part explains the development and standard types of the prefabricated wooden houses.

This work dealing with problematic about durability of concrete, with use of recycled concrete and addition of silica additions. Predominant for resistance of concrete constructions is surface layer, through which aggressive gases and liquids penetrate from surrounding environment. The most important indicator of concrete durability is ability of surface layer transmissions of aggressive substants. In the next part were defined the actual state of surface layer by normal testing methods. The transmissions of surface layer were tested on concrete cubes. Tests for transmissions of air (method TORRENT), of water (method ISAT), of acid gases (dept of carbonation by quick test in 98% CO2) were carried out and also strength tests. Assessment of positive or negative influence of additions and amount of cement on durability and mechanical properties of concrete will be discussed in conclusion.

It is presently in construction increasingly seen a return to natural materials. This trend is closely related with the ever increasing demands for improving the energy performance of buildings and also the reduction of environmental burden on the industry to the environment. During application of natural insulation materials, however, still face with two main disadvantages of these materials. It is their moisture sensitivity associated with a porous material structure, and then an adverse reaction to fire. The paper is devoted to the study of the moisture behavior of fibrous thermal insulation materials, fiber-based modified chemical additives in order to improve their moisture sensitivity.

New Civil Code enacts special type of solidary obligation to remedy the defects of building constructed under contract for works. All subcontractors (suppliers) of constructor, investor`s technical supervisors or construction project designer are solidary responsible together with the constructor in case the defect can be attributed to the performance they provided. However, these parties need not to be the parties to the contract for works itself (and usually are not) as their obligation arises by law.

The remedies that the investor can claim on these co-debtors, however, are limited to right to demand the repair of the defect. Investor may demand remedy on any of the co-debtors and all the co-debtors are obliged to perform the remedy in full.

The investor has to give notice to the debtor within a reasonable time. The notice can be sent to any of the co-debtors but we advise all investors to give notice always to the constructor first or together with the other co-debtors.

The thesis deals with urban sprawl and suburbanization as the effects of changes in society. It presents the basic historical overview and describes the situation in contemporary Europe. The thesis focuses on description of negative aspects, in connection with formed urban sprawl.

This work presents and describes the historical background of suburbanization in the Czech Republic. It reflects on the causes and presents the facts, leading to their understanding.

The practical part of the thesis is the application of acquired knowledge on the model, which is Brno-Útěchov. One of the peripheral parts of Brno that has grown significantly due to suburbanization in last few years.

Ideological study aims to show an alternative approach to this way of development. The main areas of interest are importance of public and private space, often neglected idea of neighborhood and the importance of privacy in terms of new houses in a face of village itself.

zpět na aktuální články